In recent years, the construction world has been undergoing a quiet but powerful transformation. Across the country, builders, architects, and homeowners are beginning to rethink the way homes are built, trading traditional wood framing for something stronger, smarter, and more sustainable. Insulated Concrete Form, or ICF, construction has been gaining traction nationwide, not as a passing trend but as a long-term shift in how people think about durability, energy efficiency, and resilience. The numbers tell a compelling story, and the data is clear—ICF is reshaping the American building landscape.

A Growing Movement in Construction

The adoption of ICF construction has accelerated dramatically over the past decade. According to the Insulating Concrete Forms Manufacturers Association (ICFMA), the North American ICF market has been growing by an average of 7 to 10 percent annually. What was once a niche technique used mainly in commercial or high-end custom homes is now being applied to everything from schools and government buildings to single-family residences and multifamily developments.

In the early 2000s, only about one to two percent of residential builds in the U.S. used ICF technology. Today, that number has grown to roughly ten percent in some regions, with even higher adoption in areas prone to severe weather, such as the Gulf Coast, Florida, and parts of the Midwest. The reason for this growth is simple—builders and homeowners are discovering that ICF offers measurable advantages that traditional wood framing simply cannot match.

Energy Efficiency Backed by Data

Energy efficiency is one of the strongest selling points of ICF construction, and the numbers back it up. Studies conducted by the U.S. Department of Housing and Urban Development and the Portland Cement Association have found that homes built with ICF walls use between 30 and 40 percent less energy for heating and cooling compared to traditional wood-frame homes. The continuous layer of insulation and the airtight seal created by ICF walls drastically reduce thermal bridging and air leakage, keeping indoor temperatures stable year-round.

In addition, the R-value of an ICF wall system typically ranges between R-22 and R-28, depending on wall thickness and foam density. However, when factoring in thermal mass—the ability of the concrete to absorb and store heat—the effective performance is even higher. Some experts estimate the equivalent R-value to be closer to R-50 in practical use, especially in climates with large temperature swings. This means homeowners can enjoy not just lower utility bills, but also greater comfort and quieter indoor environments.

Regional Growth Patterns and Weather Resilience

Certain parts of the country have seen faster ICF adoption due to regional climate challenges. In coastal areas, where hurricanes and tropical storms are a constant threat, ICF homes are becoming increasingly common. For example, in Florida, Louisiana, and coastal Alabama, builders are turning to ICF to meet the rigorous standards of fortified home programs that require enhanced wind and impact resistance. Tests conducted by the Federal Emergency Management Agency (FEMA) show that ICF walls can withstand winds exceeding 200 miles per hour and resist debris impacts that would easily penetrate wood framing.

In colder regions, such as the Upper Midwest and the Northeast, ICF’s superior insulation value translates directly into reduced heating costs. Builders in states like Minnesota, Wisconsin, and New York have reported growing demand among homeowners who want energy-efficient homes that stay warm in subzero temperatures without skyrocketing heating bills. Meanwhile, in the Southwest, ICF’s thermal mass helps keep interiors cool in desert climates, reducing the need for constant air conditioning. This adaptability to different environments is one reason the technology has become so versatile and widespread.

The Environmental Impact of Smarter Building

As the construction industry continues to focus on sustainability, ICF has become a leader in reducing the environmental footprint of new builds. The combination of long lifespan, reduced energy consumption, and minimal material waste makes ICF an eco-conscious choice. Studies from the National Ready Mixed Concrete Association show that ICF buildings generate up to 75 percent less construction waste compared to wood-frame projects. Additionally, because ICF structures require less heating and cooling over their lifetime, they emit fewer greenhouse gases.

ICF walls are also fully recyclable. The polystyrene foam used in most systems can be repurposed, and the concrete core is one of the most durable and sustainable materials available. When a structure eventually reaches the end of its life, its components can often be reused or recycled rather than sent to landfills. In a world increasingly concerned with long-term sustainability, these advantages make ICF an appealing option for eco-minded homeowners and developers alike.

Builder and Homeowner Satisfaction Numbers

Beyond statistics on energy savings and durability, the satisfaction rates among both builders and homeowners speak volumes. Surveys conducted by the ICF Builder Group found that more than 85 percent of homeowners who live in ICF homes report being “extremely satisfied” with their decision. Many cite not only the comfort and efficiency but also the peace of mind that comes from living in a home that can stand up to extreme weather.

From the builder’s perspective, the transition to ICF has become easier as technology has improved and training has expanded. Over 70 percent of contractors who have switched to ICF say they plan to continue using it for future projects. This rise in builder confidence is one reason ICF adoption is expected to keep increasing in both residential and commercial markets over the next decade.

Insurance and Long-Term Savings

Another factor driving ICF’s popularity is cost stability and insurance savings. While the initial cost of ICF construction can be 3 to 7 percent higher than wood framing, the long-term savings more than make up for it. Energy costs are lower, maintenance needs are minimal, and insurance companies often offer premium discounts for ICF homes due to their resistance to fire, wind, and flood damage.

In fact, several major insurers, including State Farm and USAA, recognize ICF homes as lower risk and reward homeowners with up to 20 percent lower annual premiums in certain areas. Over time, these savings, combined with reduced energy bills, can offset the higher upfront cost within just five to seven years. For many homeowners, that’s not just a smart investment—it’s a strategic one.

How the Market Is Responding

Developers and real estate investors are also taking notice of ICF’s economic advantages. The commercial ICF sector is growing alongside residential, particularly in schools, medical centers, and hotels, where energy efficiency and sound control are critical. A recent report from MarketWatch projects that the global ICF market will reach $1.5 billion by 2028, with North America accounting for the largest share of growth. The report also highlights that residential projects make up over 60 percent of that demand.

As cities across the country begin to adopt more stringent energy codes and building standards, the demand for ICF is expected to surge even further. Builders who have already incorporated it into their practices are ahead of the curve, ready to meet the future of construction head-on.

The Strength Behind the Numbers

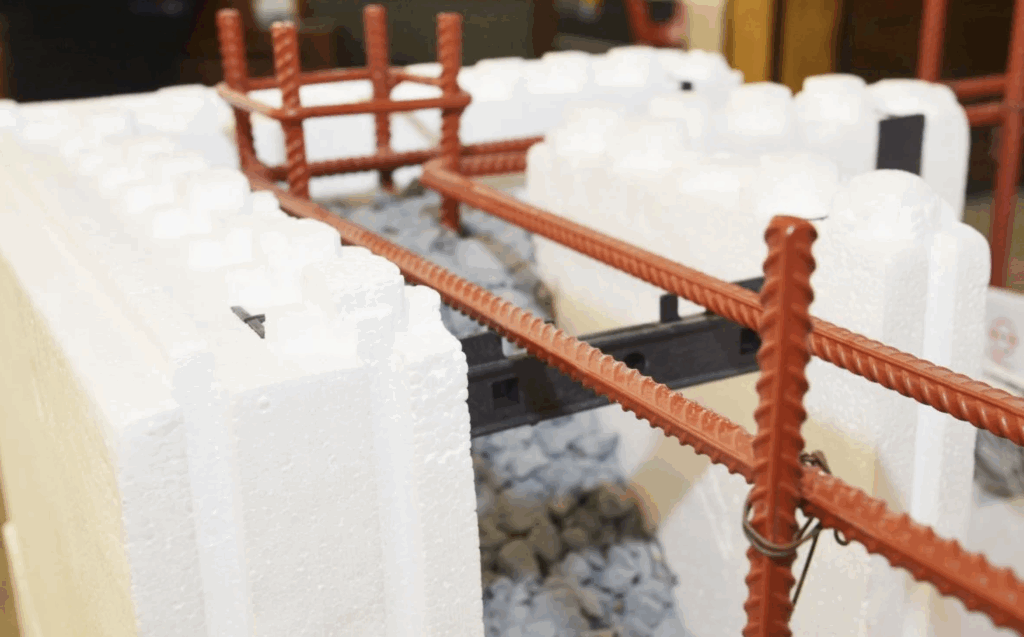

The statistics surrounding ICF construction tell a clear story, but the real strength lies in its results. Homeowners are enjoying quieter, more efficient, and more durable homes. Builders are experiencing fewer callbacks and more referrals. And communities are benefiting from stronger, more sustainable structures that can withstand the test of time and nature.

ICF walls combine modern engineering with simple, effective design principles—insulation, strength, and efficiency working together as one system. When all of these elements align, the result is a building that performs better across every measurable category, from temperature control to disaster resilience.

The Future of ICF Construction

The future of ICF construction looks exceptionally bright. As more homeowners demand energy efficiency and durability, and as builders seek smarter ways to meet stricter codes, ICF will continue to expand its footprint across the nation. Advancements in material technology are also making it more accessible than ever, with systems designed to simplify installation and lower costs. Many newer ICF block designs are modular, allowing for faster builds and reduced labor requirements.

In areas like the Gulf Coast, where weather resilience and energy savings are equally important, ICF construction is quickly becoming the go-to method for building smarter homes. Builders who specialize in this technology are not only delivering stronger homes but also setting new standards for quality and innovation in the construction industry.

Conclusion: Building Smarter, Living Better

The numbers surrounding ICF construction make one thing clear—it’s not just a trend; it’s a transformation. From measurable energy savings and lower insurance premiums to growing adoption rates and improved environmental performance, ICF offers a proven pathway to building stronger, safer, and more sustainable homes. Whether you’re a homeowner looking for long-term value or a builder aiming to stay ahead in a competitive market, the evidence points to one undeniable conclusion: ICF construction represents the future of smart, resilient building.

Across the nation, from coastal communities to cold-weather cities, more people are making the switch. The data supports it, the results prove it, and the future depends on it. With every ICF project completed, the construction industry moves one step closer to a new standard—one where strength, efficiency, and sustainability work hand in hand.